ALEX’s Holiday Gift Guide 2023

For gift-giving this year, we’re all about experiences that make memories for you and your loved ones! Read on for ALEX’s ideas on how to add a little sprinkle of science to your holiday gift-giving.

Go Behind the Science Scene…

Give the gift of a wildlife encounter! Zoo Atlanta has lots of experiences to choose from, including encounters with pandas, lemurs, and elephants. You can also purchase a general wildlife encounter gift certificate and let your giftee choose for themselves! Or take your encounter underwater with an aquatic creature encounter for the aquarium lover in your life. Georgia Aquarium has lots of experiences to choose from, including encounters with sea lions, dolphins, and beluga whales.

Gift a Membership…to Science!

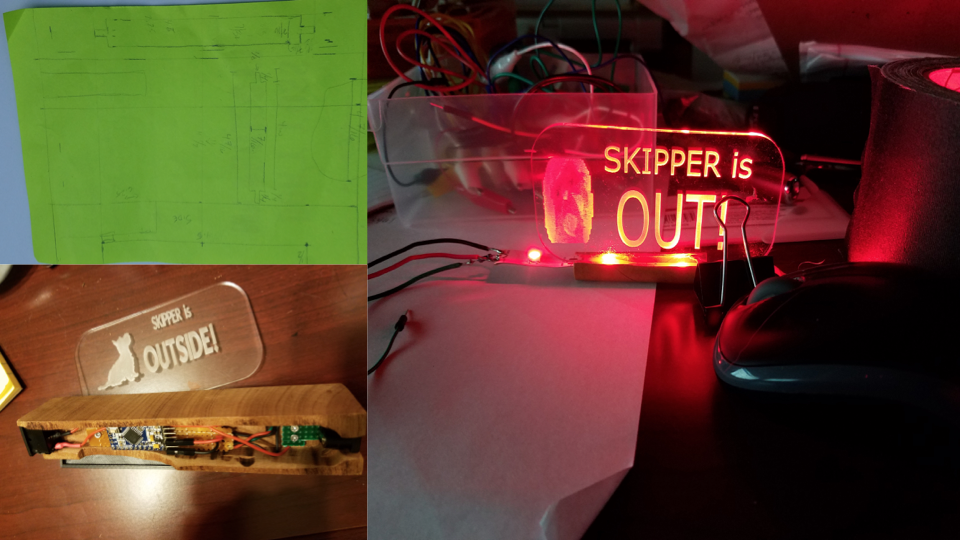

Whether your giftee likes botany, birding or building, Atlanta’s got it! A membership to the Atlanta Botanical Garden is a great gift for your favorite plant-lover that includes a nice set of benefits, including free daytime admission and discounts on educational programs. Maybe you prefer birds to plants? Try out a membership to Birds Georgia (formerly Georgia Audubon). This membership comes with access to the brand new Morgens Environmental Education Gateway: a one-stop shop for educational content focused on birds. Purchase of a gift membership includes a welcome letter, the most recent copy of Audubon’s quarterly newsletter, Wingbars, and a Birds Georgia sticker. Or perhaps your giftee is more of a doer than a watcher. In that case, give a gift membership to the Decatur Makers space! You will be shipped a membership gift certificate for your recipient. Membership comes with a key fob with 24/7/365 maker space access, access to equipment and tools, free or discounted classes, workshops, and events. Members are also allowed to bring visitors to the space!

Get Your Science Outside…

How about a “Sustainability in Action” tour with Bike Tours of Atlanta? This tour is a great way to learn more about how Atlanta has embraced sustainable practices and innovations. This experience is presented in partnership with Root Local, a local nonprofit focused on supporting collective environmental impact within metro Atlanta. Or for the nature lover, give a Georgia State Parks gift card which can be used for camping, cottage or shelter reservations, historic site admission, greens or cart fees, and retail and recreation fees. Or you can even give the gift of a year’s worth of entry into affiliated parks! Extended passes include free nights of camping, discounted lodging, and discounts on picnic shelters.

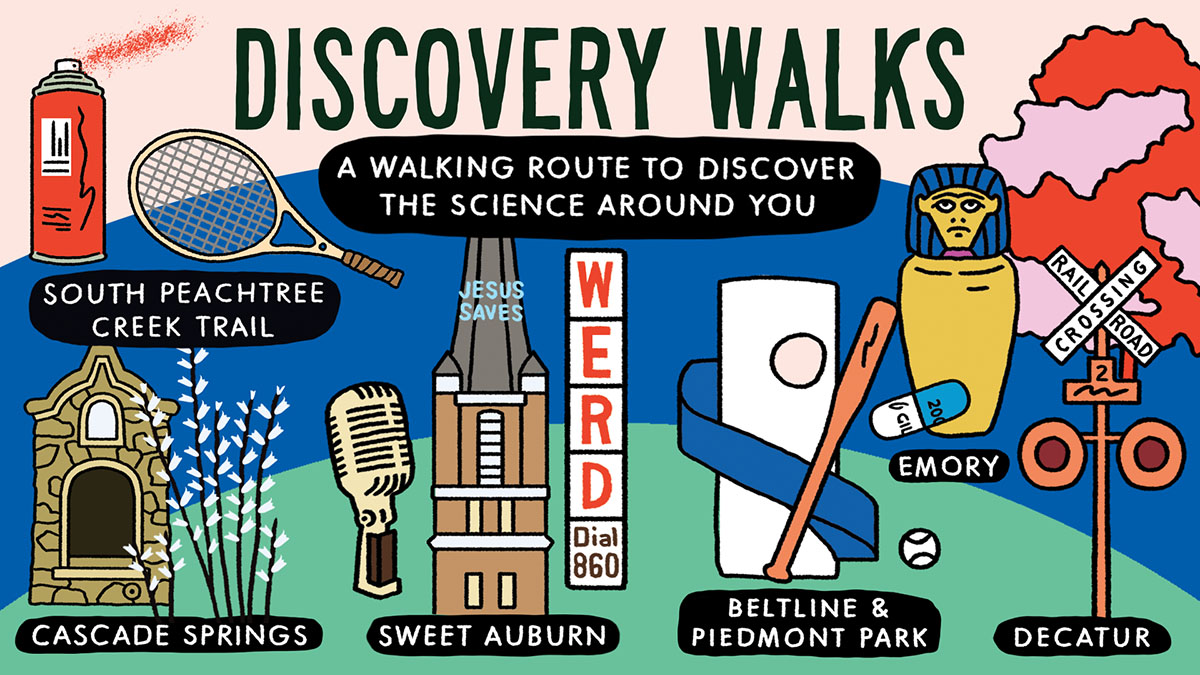

At Science ATL, we also offer maps for purchase to go on your own family-friendly science discovery walk. We partnered with a local artist to develop these six beautiful maps for you to take a self-guided Discovery Walk, each with ten intriguing science stops. Take your family and friends on a science adventure through some of the coolest neighborhoods and parks in Atlanta, including Cascade Springs, Sweet Auburn, Emory University’s campus, the South Peachtree Creek Trail, Decatur, and the Beltline & Piedmont Park. While you are purchasing some of these maps, check out our collection of shirts and stickers!

Eat and Drink Your Science…

Remember that science is everywhere! For the grown-ups in your life, consider a class about food and drink and give them the chance to ask all their nerdy questions! Elemental Spirits offers custom experiences and tastings to let you learn all about wine and cocktails. Or send your giftee to a class on how to brew the perfect cup of coffee with Opo Coffee. Opo will be hosting special classes during the Science Festival in 2024, but you can sign up for classes like Coffee Roasting Basics or Home Espresso Making anytime! Prefer to eat your science? Dig into cheesemaking with classes from Capella Cheese. You can eat your way across Europe with a wide variety of courses from these master cheesemakers!

Read Your Science…

Immerse yourself in the world of science through reading. ALEX compiled a list of books written by Georgia authors (marked with 🍑), and tossed in a few from the finalist list for the 2024 American Association for Advancement in Science/Subaru Prize for Excellence in Science Books (marked with ⭐). If you are able, stay local with your purchases. Little Shop of Stories, A Capella Books, and Virginia Highland books are some of our favorites in the metro Atlanta area.

For Adults

Life Sculpted: Tales of the Animals, Plants, and Fungi That Drill, Break, and Scrape to Shape the Earth, Anthony J. Martin 🍑(more from Tony here.)

The Plant Hunter: A Scientist’s Quest for Nature’s Next Medicines, Cassandra L. Quave🍑

Big Chicken Maryn McKenna 🍑(more from Maryn here)

Wild Spectacle, Janisse Ray 🍑

A Road Running Southward: Following John Muir’s Journey through an Endangered Land, Dan Chapman 🍑

Odyssey: Young Charles Darwin, The Beagle, and The Voyage that Changed the World, Tom Chaffin 🍑

For Young Adults (Grades 9–12)

The Milky Way: An Autobiography of Our Galaxy, Moiya McTier ⭐

The Sounds of Life: How Digital Technology Is Bringing Us Closer to the Worlds of Animals and Plants, Karen Bakker ⭐

Wilder: How Rewilding is Transforming Conservation and Changing the World, Millie Kerr (preorder) ⭐

Wildscape: Trilling Chipmunks, Beckoning Blooms, Salty Butterflies, and Other Sensory Wonders of Nature, Nancy Lawson ⭐

For “Middle Grades” (Grades 5–8)

Good Food, Bad Waste: Let’s Eat for the Planet, Erin Silver ⭐

How Do Meerkats Order Pizza?: Wild Facts about Animals and the Scientists Who Study Them, Brooke Barker ⭐

The Planets Are Very, Very, Very Far Away: A Journey Through the Amazing Scale of the Solar System, Mike Vago ⭐

Superpower?: The Wearable-Tech Revolution, Elaine Kachala ⭐

For Younger Kids (K–4):

Before Colors: Where Pigments and Dyes Come From, Annette Bay Pimentel ⭐

Science of Baking (Ada Twist, Scientist: The Why Files #3), Andrea Beaty and Dr. Theanne Griffith ⭐

We Go Way Back: A Book About Life on Earth and How it All Began, Idan Ben-Barak ⭐

Whale Fall: Exploring an Ocean-floor Ecosystem, Melissa Stewart ⭐

And The Tide Comes In… Exploring a Coastal Salt Marsh, Merryl Alber 🍑

Bug Scouts #1: Out in the Wild!, Mike Lowery 🍑

Because of an Acorn, Lola M. Schaefer 🍑

Owly series, Andy Runton 🍑

“Hands On” Science Books (Grades K–8):

Human Body Learning Lab: Take an Inside Tour of How Your Anatomy Works, Dr. Betty Choi ⭐

Sheet Pan Science: 25 Fun, Simple Science Experiments for the Kitchen Table; Super-Easy Setup and Cleanup, Liz Lee Heinecke ⭐

Wild Child: Nature Adventures for Young Explorers—with Amazing Things to Make, Find, and Do, Dara McAnulty ⭐

The Kitchen Pantry Scientist Ecology for Kids: Science Experiments and Activities Inspired by Awesome Ecologists, Past and Present, Liz Lee Heinecke ⭐

Support Your Science…

If you love events like the Atlanta Science Festival and Science ATL LABS: Shark Dissection, please consider supporting the work we do with a donation in honor of your giftee. Your gift to Science ATL helps support our mission of cultivating an equitable community of lifelong learners across metro Atlanta connected and inspired by the wonder of science.

By Misael Romero-Reyes

By Misael Romero-Reyes