Up Close and Personal with The Amphibian Foundation

By Lucy Cronin-Golomb

By Lucy Cronin-Golomb

Amphibians are secretive little critters. They like to hide in the comfortable corners of woodlands, marshes, and swamps. When you go on a walk in the woods, you might find an amphibian burrowed under a log or tucked into the corner of a stream. We don’t see amphibians all the time, so sometimes it is easy to forget they are there. Yet their presence is insurmountably important. Amphibians are crucial for the control of bug populations. They also provide a valuable food resource for creatures such as birds and snakes. Without amphibians, certain ecosystems become vulnerable to collapse.

I sat down with Crystal Mandica, the Director of Education at the Amphibian Foundation, to learn more about these enigmatic creatures and her work connecting the public to them. “It’s so important,” Crystal says, “To teach everyone, from the really little kids all the way to adults, about amphibians.” Especially since, as Crystal explained, more and more species of amphibians are going extinct. In Georgia alone, there are 7,000 species of amphibians. 2,500 of those are on the edge of extinction or are already extinct. They are losing their habitats to clearcutting of forests and suffering from nasty, suffocating diseases, like the creepy chytrid fungus. Education is critical because a lot of people don’t realize how many amphibian species are in danger. It is important to learn how we can help before it is too late.

Amphibian Conservation and Education

Have you ever seen a frosted flatwoods salamander? This little creature has lost 98% of its natural habitat. At the Amphibian Foundation, there are special, safe areas where the salamanders have plenty of room to live and grow. Once the adults lay eggs, those eggs are brought back to the wild to help repopulate the species. It can be tricky to successfully breed amphibians in captivity. But the Amphibian Foundation has found success- early this year, they announced they had successfully bred the frosted flatwoods salamander in captivity for the first time! There are eight other at-risk species at the Amphibian Foundation to learn all about too.

Crystal leads the education charge at the Amphibian Foundation. They host both informal events and formal educational opportunities throughout the year to tell the public stories of the frosted flatwoods salamander and friends and the work the Foundation is doing to preserve them.Check out one of the many classes and camps for people of all ages to learn about and appreciate amphibians.

For Crystal, reaching people of all ages is especially important. “It is good to encourage even the really little kids to learn about these creatures as early as they can, so they know they exist and can appreciate them!” She offers Critter Cafes, where small children can see and touch frogs and salamanders, and, for older kids, there are Critter Camps during the summer, where they can explore various woodland areas, flipping logs and scouting out streams. The best part of the camps, Crystal says, is “Snake Day,” which comes at the end. While some campers are initially nervous about Snake Day, after a week of learning about amphibians, campers are excited and ready to meet their slithery friends.

For adult learners, they offer the Master Herpetologist program. This program is one of the foundation’s most popular, reaching 250 students per semester. A “Junior Herpetologist” program is also in the works. If you are looking for a unique way to celebrate your birthday, The Amphibian Foundation has Critter Birthday Parties where you can have amphibian guests mingle among your friends. Crystal hopes to add more and more classes, events, and camps in the next couple of years.

Amphibians like to hide and tend to shy away from the spotlight. But now more than ever, it is important that we are aware of them. They need our help to survive. At the Amphibian Foundation, Crystal is doing the crucial work of shining the light on amphibians, through both education and conservation. Learn more about ways you can help contribute to the education and conservation efforts of the Amphibian Foundation!

Atlanta-Area STEM Summer Camps

Below is a list of STEM-themed 2022 summer camps in the metro Atlanta area submitted and hosted by Science ATL Partner organizations. This list, presented in no particular order, is intended to support parents seeking awesome science experiences for their kids this summer. Always check the website for more details about the camps and any changes to program structure due to unforeseen circumstances.

Disclaimer: Inclusion of any organization, activities, products, or services on this webpage does not constitute or imply the endorsement, recommendation, or favoring of the Science ATL Inc., or any of its employees or contractors acting on its behalf.

The Amphibian Foundation – Critter Camps

Dates: Weekly from June 6 to Aug 12, 2022

Ages: 5-15 yrs

Location: Decatur and Buckhead

Contact: ribbit@critter-camp.org

Critter Camp is a fun, science-based exploration into the world of reptiles and amphibians – perfect for the critter enthusiast in your life! Campers are encouraged to ask questions about the animals and discover their own answers through hands-on observation. Safe animal handling, including biosecurity, will be taught and implemented at the beginning of the camp, and maintained vigilantly throughout.

Size, schedule, and pricing varies by location. Check the Critter Camp website for more information.

Daily Hours:

9am-3pm: Friends School of Atlanta Location

9am-4pm: The Amphibian Foundation Location

Before care and after care available

Registration open now

Trees Atlanta – Junior Treekeeper Camps

Dates: Weekly from May 31 to July 29

Ages: Open to rising 1st to 6th graders

Location: Trees Atlanta Kendeda Center, 225 Chester Ave., Atlanta, GA 30316

Contact: education@treesatlanta.org

Junior TreeKeeper Camp days are filled with adventures in the urban forest. Kids spend time doing hands-on activities in environmental science, biking to explore the Atlanta BeltLine Arboretum and green spaces, and making new memories with friends. Each week has a different session theme – from Breathe with Trees to Pollinator Power to Animals in the Forest and more.

Daily Hours: 9am – 3pm Before and Aftercare are available

Registration open now

O-Academy

Dates: June 6 to July 29

Ages: 5-12

Location: Outdoor Activity Center 1442 Richland Rd. SW Atlanta, GA 30310

Contact: anamarie@wawa-online.org

Camp at the Outdoor Activity Center (OAC) provides youth, ages 5-12, with a safe and supportive place to explore nature and help care for our environment. Hosted by West Atlanta Watershed Alliance, our experienced staff are environmental educators and certified interpretive guides, who foster outdoor skills. They are caring, creative and will help your child make meaningful connections to nature.

Daily Hours: 9am-4pm

Registration opens in March

The Neuroscience School

Dates: June 13 to July 15

Ages: Rising 9th-12th graders

Location: Virtual

Contact: neuroscienceschool@gsu.edu

Sponsored by The Center for Behavioral Neuroscience The Neuroscience School at Georgia State University offers short courses in the summer for any high school students who enjoy science. These week-long engaging courses are taught by award-winning neuroscience and psychology professors, all of whom hold interest and scholarly expertise in science education research and programming.

Daily Hours: 10am – 4pm

Registration is open

Exploring Engineer STEM Academy

Dates: June 6-10

Ages: Rising 9th-12th graders

Location: Georgia Tech Campus, Atlanta, GA

Contact: RMORALES@LBFOSTER.COM

The oldest and largest secondary school academy in the nation dedicated toward STEM careers is celebrating our 22nd year on the Ga Tech campus. Academy students learn about the various fields of Engineering and Science from hands-on experiences and visiting exciting tours of high-tech facilities & laboratories. Students come from Metro Atlanta, all over Georgia, as well as across the country, exploring how to become a successful Engineer or Scientist!

Daily Hours: Residential with adult supervision provided in the dorms

Register before March 1 for a reduced price

EnviroVentures Summer Camp

Dates: June 6 to July 29

Ages: 5-13 (Counselor In Training program for ages 11-13)

Location: Community Center at Piedmont Park Conservancy, 1071 Piedmont Ave NE Atlanta, GA 30309

Contact: mkowalski@piedmontpark.org

Camp includes a healthy and engaging activity schedule featuring outdoor sports and recreation, STEAM focused activities, exploration of the Park, arts and crafts, park stewardship, special programs and much more! All full day campers participate in daily swimming at our Aquatics Center.

Daily Hours: 9am – 4 pm Before and Aftercare are available

Registration open now

Summer P.E.A.K.S

Dates: June 6 to July 29

Ages: Rising 2nd to 12 grades

Location: Georgia Institute of Technology

Contact: roxanne.francis@ceismc.gatech.edu

CEISMC Summer P.E.A.K.S. (Programs for Enrichment and Accelerated Knowledge in STEAM) are one week long experiences designed to increase Science, Technology, Engineering, Art, and Mathematics (STEAM) knowledge through various educational activities. Summer P.E.A.K.S. give students the chance to enhance learning during the summer in experiential activities on campus at Georgia Tech.

Daily Hours: 9am – 3 pm

Registration opens in February

CDC Museum Disease Detective Camp

Dates: June 27 to July 1 and July 25-29 and August 8-12

Ages: Rising Juniors and Seniors (Must be 16 by the first day of the camp session)

Location: CDC headquarters

Contact: cdcm_phacademy@cdc.gov

CDC Museum Disease Detective Camp is an interdisciplinary educational program organized by the CDC Museum. During camp students are immersed in the diverse field of public health. Topics vary year to year, but may include: public health interventions, global health, infectious disease, chronic disease, injury prevention, data analysis, surveys, school wellness programs, violence prevention, environmental health, emergency preparedness, outbreaks, scientific communication, laboratory technology, disease surveillance, epidemiology, and public health law. Camp is a fast paced, academically demanding program. Participants are expected to fully immerse themselves, work together, and become a diverse team of disease detectives!

Daily Hours: 8:45 am – 4pm

To apply for the 2022 CDC Museum Disease Detective Camp first read the FAQs, next download, and complete application, then submit it by mail. Applications must be post-marked (mailed) by April 1, 2022.

CDC Museum Public Health Academy Online Summer Course

Dates: June 13- 17 and July 18-22

Ages: Rising Juniors and Seniors (Must be 16 by the first day of the camp session)

Location: Virtual

Contact: cdcm_phacademy@cdc.gov

The CDC Museum Public Health Academy Online Summer Course is a web-based course with both synchronous and asynchronous components. Topics vary course to course, but may include: public health interventions, global health, infectious disease, chronic disease, injury prevention, data analysis, surveys, school wellness programs, violence prevention, birth defects, mental health, environmental health, emergency preparedness, outbreaks, scientific communication, laboratory technology, disease surveillance, epidemiology, and public health law. The course is a fast-paced academic program. Participants are expected to immerse themselves in all course materials and complete daily assignments by given deadlines in the week.

To apply for the 2022 CDC Museum Academy Online Summer Course first read the frequently asked questions next download and complete application, then submit it by mail. Applications must be post-marked (mailed) by April 1, 2022.

Bugs, Bytes & Bites Discovery Camp!

Dates: June 20-June 24

Ages: 8-11 years old

Location: Grub-Ah-Dub Shack | 1016 Monroe Drive, NE, Atlanta, Georgia 30306

Contact: info@wundergrubs.com

Explore and discover science through the wonderful world of insects at the Grub-Ah-Dub Shack. From sensors to food waste, campers will explore and investigate innovative ways to farm insects. With Mealworms as their inspiration, campers will tour sustainable farms, create interactive art, play fun games and go on Entomology adventures.

Daily Hours: 9am – 4 pm

Registration opens in March

I AM STEM Camp

Date: June 20 – July 15

Ages: K-12

Location: Virtual and multiple in-person options will be available

Contact: natalieking@iamstemcamps.com

I AM STEM Camp is designed to expose K-12 children to the world of science, technology, engineering, and mathematics through real-world experiences and exciting lessons. Our curriculum is taught by certified teachers and STEM professionals. There are virtual and face-to-face options available that center social justice and expose participants to STEM careers.

Daily Hours: 9am – 3 pm

Registration opens in March

Park Leadership Team @ Piedmont Park

Dates: June 6 – July 1

Ages: 14-15

Location: 1071 Piedmont Avenue NE

Contact: kwalker@piedmontpark.org

The Park Leadership team is a great way for youth ages 14-15 to be Park Ambassadors. The team will participate in a range of activities including: engaging with Park visitors, participating in public programs in the Park and developing and producing creative content for Park learners. All while getting to spend summer in the Park with their peers! Each week the Park Leadership Team will complete a service project in the Park like building a Little Free Library or working to create a new pollinator garden or painting an educational art piece in the Community Garden.

Daily Hours: 1pm – 5 pm

Registration opens in February

High Touch High Tech

Date: All Summer

Ages: 4-11

Location: Online and In Your Neighborhood!

Contact: info@sciencemadefulatl.net

High Touch High Tech has designed several ways to engage with their hands-on STEM content this summer. They can bring their content to your camp or neighborhood group weekly or for a weeklong half-day program. They also have 5 pre-recorded 60-minute Virtual Programs that can purchased individually or as a “Camp in a Bag” for over 50 different experiments. All supplies are included in the cost. Themes include Geology, Plants, Brains, Rockets, Sound and more.

Being the CEO of ME

Date: June 6 to July 29

Ages: 5-18

Contact: Josette@metincpowerco.org

For (2) four weeks sessions, Being The CEO of ME Prodigy Campers (elementary school) and Being The CEO of ME YLA campers (middle and high school) are taught how to create and market a product line in the industry of their choice.

Being The CEO of ME blends STEM, entrepreneurship, and social impact in a vibrant and fun learning environment where campers are encouraged to explore their interests in tech and E-commerce while finding opportunities to turn their big ideas into realities. They collaborate in teams, participate in scavenger hunts, learn about their local economy, and finish community projects with the help of mentors from local businesses, tech companies, and local colleges and universities that help them understand the importance of civic leadership, and creating solutions to everyday problems where they live and play.

Daily Hours: 8am – 5PM

Summer Flyer and Registration available in March

Project Smart

Date: June 7 to June 17

Ages: 8-10

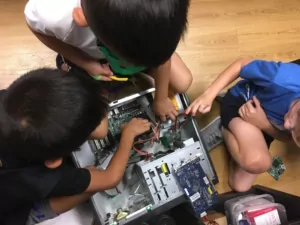

Project SMART immerses elementary students in Science, Technology, Engineering, Arts, and Math (STEAM) that empowerstudents to be innovators and problem-solvers all while having fun! Students uncover how to create SMARTer communities through coding, creativity, and collaboration.

Students will learn about SMART Cities and explore questions like: How are science, technology, and math utilized in SMART Cities? How do you identify community issues and create solutions to address them? And how to write basic computer code to present solutions and products?

Daily Hours: 8am-12pm

More information and registration will be available in March

Club SciKidz STEM Day Camps

Ages: Rising PK – 8th

Locations: Nine metro-Atlanta locations (see website)

Contact: ed@clubscikidz.com

At Club SciKidz, we know that you want to be the parent who chooses the best camp for your kid. To do that, you need a fun and safe camp where your child will learn new skills from positive role models. The problem is planning your kid’s summer activities can be overwhelming. We believe you can plan a great summer experience for your kid. We understand, we have kids, and our children’s well-being is our top priority, which is why we’re proud that 70% of our campers each year come from referrals and repeat business. So, join us this summer. Don’t miss out on opportunities for your kid to thrive, and instead, your kid will be engaged learning new skills with like-minded friends and beg you to come back.

Daily hours: 9 AM – 4 PM (Before and Aftercare available)

Registration: https://atlanta.clubscikidz.com

SUMMER SAFARI CAMPS AT ZOO ATLANTA

Dates: May 31, 2022 – July 29, 2022

Ages: 5-14

Location: Zoo Atlanta

Contact: education@zooatlanta.org

Join us for an exploration of all things WILD! From pandas to parrots to pine snakes, young explorers will be immersed in hands-on, minds-on learning while having fun! Zoo Atlanta’s Safari Camp: Summer Session is the perfect summer break experience for children ages 5 to 14. Each week campers embark on a different Zoo expedition, exploring wildlife and wild places. From Conservation Champions to Survival of the Fittest, participants will be engaged in ways they can save wildlife and wild places. Select an individual week that fits in your summer plans, or spend the entire summer with us. For more information please visit. Each week campers embark on a different Zoo expedition, exploring wildlife and wild places. For more information please visit the Zoo Atlanta website.

Times: Safari Camp hours are 9 a.m.–4 p.m. (Drop-off starts 8:30 a.m.) Extended care available for $75 per week from 8 a.m. – 8:30 a.m. and 4:30 p.m. – 5 p.m.

“IT GIRL” SUMMER SERIES

The ‘IT Girl’ Summer Series is a four week digital and hands on exposure learning camp for girls ages 8-16 to learn in-demand technology concepts. Additionally, our workshops and programs focus on discovering, pursuing, and succeeding in technology through the exposure of technical concepts. Students do not need to have any prior technical experience, and all materials will be provided. We ask all students at least have a strong desire to learn more about technology.

Session 1: Intro to Technology for Beginners, June 4th- June 25th, 9:30-11:30am, Ages: 8-12

This program is designed to engage young minds and help them advance from being merely computer users to creators. Participants will learn the basics of technology, history, and creating using computers through activities. They will apply their programming skills to create simple programs, animations and games.

Session 2: Intermediate Web Design, June 4th- June 25th, 12-2pm, Ages: 13-16

This program teaches students how to build their own web pages. Students will learn the languages HTML and CSS, and will create their own live homepages to serve as portfolios of their creations. By the end of this course, students will be able to explain how web pages are developed and viewed on the Internet, analyze and fix errors in existing websites, and create their very own multi-page websites.

More at the Next IT Girl website.

The Science of Good Dirt at CompostNow

By Donna McDermott

I visited King of Crops farm on the first cool morning of September. Last night’s rain had left a cloudy, golden glow over rows of blueberry, muscadine, and persimmon that would soon become popsicles sold under rainbow umbrellas. But I didn’t go to King of Crops for the fruit. I was there to meet David Paull, CompostNow co-founder and CIO.

About CompostNow

CompostNow collects food scraps from residents and businesses to help them reduce waste and support local gardens. The farm where I met Paull is less than an hour from Midtown, yet nature sprawled out around us with a vigor you rarely see in a city garden. In amongst the fields were tulip tree saplings, goldenrod blooms, and, of course, decay. This is the kind of decay that makes room for new growth.

David Paull, CompostNow co-founder and CIO

As we start our conversation, Paull speaks about his longtime commitment to agriculture that works in harmony with nature. These days, his goal with CompostNow is “to develop the vitality in our soil systems on a larger scale.” His goal of cultivating healthy gardens appears to have grown and flowered. Pokeberry branches fruiting around the skeleton of a long-abandoned greenhouse are one of the few signs that, years ago, this land was home to an ornamental nursery.

The compost piles are about as tall as I am, with dimensions slightly smaller than a school bus. The pile closest to the road is flecked with mysterious white and green streaks. Piles farther from the road are older, richer, and have become a uniform dark brown. As we walk toward the compost, I smell a slight, mellow funk. This is decomposition at work.

Piles and Piles of Compost

This isn’t just any dirt.

The labor of composting is largely here, right at the piles. Workers pick out trash that won’t decompose, filtering out the mistakes that sneak into composters’ buckets. (Or, maybe “mistakes” is the wrong word. Unusual finds in this compost pile include a life-size steel dog statue.) Once the piles are cleared of contaminants, microbes take over the work.

Microbes are organisms that are too small for the human eye to see. This group includes bacteria, small funguses, algae, and other single-celled creatures. And there is a diverse microbe community living in all healthy soil. This microbe community helps plants absorb soil nutrients and also decompose. Different species of microbes grow at different temperatures. Paull measures a pile where microbes are thriving at 136°, while a freshly turned pile would have microbes that work best around 150°. High temperatures like these are essential for safely composting materials like meat and dairy. In contrast, home compost piles are smaller and therefore colder, so meat and dairy products often can’t be included. In a colder compost pile, meat and dairy products don’t decompose all the way. Meat and dairy scraps breed different communities of microbes that can be harmful to human health. These differences in microbe community are why the small compost pile in someone’s backyard is likely to only contain raw vegetable scraps.

The Science of Good Dirt

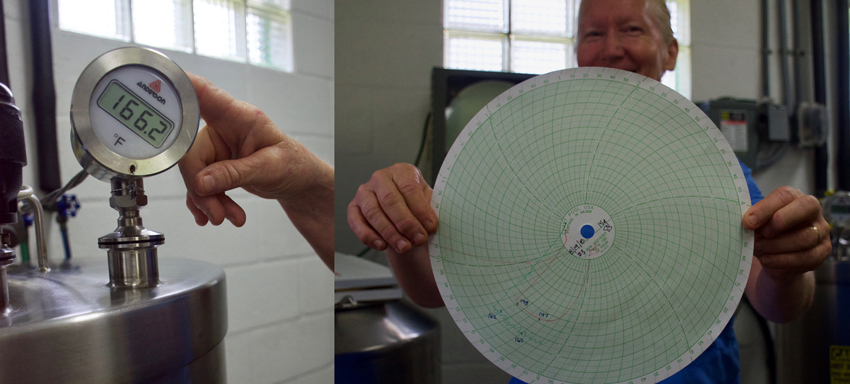

Monitoring the temperature of the compost pile.

CompostNow has the capacity for huge compost piles that are consistently maintained by skilled workers. Because these piles always reach high temperatures, consumers can safely include meat and dairy products in their CompostNow bins. The workers at CompostNow carefully control pile temperature by accounting for a range of factors: pile size, the frequency with which the piles are turned, airflow through the piles, water content. It’s this maintenance that makes composting so easy since customers don’t need to think about which foods are going into their CompostNow bin.

The microbe decomposers take their time in fully decomposing food scraps down into soil nutrients. These piles will mature for about nine months before they’re ready. Most of the compost here will stay on the King of Crops farm, helping to fertilize the soil that has long been neglected. CompostNow also sends compost to community gardens around Atlanta and to the customers that submit compost in the first place. Give out food scraps, receive soil nutrients in return. This process of rot and rejuvenation might not seem romantic, but compost piles are nature at its finest. Cycles of growth are regenerated here, by the slow, steady effort of humans and bacteria and fungi.

The Cost of Composting

The biggest challenge of composting is the stage where waiting isn’t an option: the very beginning. The logistics of moving food scraps from dinner plates to dump trucks are complicated. To solve this puzzle, CompostNow uses their own original software to create routes between composting customers while tracking data on the company’s collection and production. The customers are the fuel behind this operation. Customers’ food scraps generate nutrient-rich soil while their monthly fees support the staff that maintains healthy compost piles. Still, most customers never see the farm where their waste turns into new food. So why do customers sign up?

I signed up for CompostNow for the same reasons that David Paull began community composting in Atlanta in the first place. As Paull describes it, agriculture is “the basis of a healthy community.” But unfortunately, our mainstream agriculture system “goes totally against the way that we could be producing food and how we think about our waste in general.” Paull points out that it’s a problem to think of food scraps as waste, yet many people do; 97% of food scraps generated in the US are dumped in landfills and the US produces more than 100,000 tons of landfill waste annually. These tons of waste are costly.

The cost of composting goes toward building a sustainable culture.

Paull explains that some potential customers balk at the price of monthly compost pickups. He argues that throwing food scraps in the trash can isn’t free, either. (In Atlanta, the base rate for garbage pickup is more than $300 per household each year.) The cost of conventional trash pick up is especially high if you consider the long-term costs. For example, Paull lists, “The cost to maintain those landfills, the cost of environmental degradation, the cost of, you know, the fact that our climate is changing rapidly. We’re experiencing more extreme weather conditions than we have ever before… So, if… you think that you don’t pay for waste, you absolutely pay for waste.” In Paull’s opinion, the cost of composting goes toward building a sustainable culture.

Sustainability is not just a matter of microbes and trash and dirt; it’s about people. For healthy ecosystems to thrive, the people inside them need to, also. At CompostNow, Paull explains, “People have to be able to have health insurance. They have to be able to go from being a college student… to someone that’s interested in developing a life with potentially a family.” This ethos is why CompostNow’s minimum wage is $15 an hour. This respect for workers is a heartening contrast from conventional trash pickup services. Though conventional trash collectors make a similar wage (median hourly wage in the US is $17/ hour), they risk injury and death in the collection process. Trash and recycling collection is one of the most dangerous jobs in the country, according to the US Bureau of Labor Statistics. In contrast, CompostNow’s commitment to the environment includes prioritizing the needs of people in their community, including both those on the farm and out in the world.

Community & Sustainability

Connecting with community members about sustainability is the foundation of CompostNow. Paull describes how exciting it is to host conversations with composters: “If we can stand at a farmer’s market and be the enthusiastic champions of compost, where someone can come up to our table and literally exclaim their passion for their backyard compost pile to us and just share that to us, that is an amazing opportunity and we treat that very seriously.”

Get Involved

Would you like to join in on the compost conversation? You can visit CompostNow online. If you’re extra excited — or extra tentative— you can talk to a CompostNow expert at the Grant Park Farmer’s Market, Peachtree Road Markets, or Freedom Farmers Market. Global ecosystems may be changing rapidly, but businesses like CompostNow are a nice reminder that there’s still time to connect to your environment. Don’t miss the opportunity to walk down tree-lined park paths early in the morning, hot coffee in hand, and ask a stranger what to do with your dirt.

Thank you to CompostNow and David Paull for walking us through the science of good dirt. Stay tuned to our website, Facebook, Twitter, and Instagram for more Awesome Science of Everyday Life features and other science updates!

The Science of Cross Country Running Training

By Owen Beck

“Is this normal?” asked Agnes Scott College’s newest head Cross Country Coach, Molly Carl, referring to a 90-degree fall day last year, “Shouldn’t it have cooled off a bit by now?” Welcome to Hotlanta!

While this Northerner may still be acclimating to Georgia’s sweltering heat, Coach Carl is very familiar with successful cross country running. Prior to arriving to Agnes Scott College, Coach Carl was a standout cross country and track athlete at Southern Maine University. Following undergrad, she was an Assistant Cross Country Coach while obtaining her Master’s degree in Exercise and Sport Studies at Smith College. Coupling her experiences and enthusiasm for the sport, Coach Carl is ready to lead the Agnes Scott Scotties to cross country prominence.

Collegiate cross country running is usually between 2 to 3.7 miles on non-paved paths and is an intensively aerobic exercise. In other words, it is exercise that improves and requires the body to absorb oxygen efficiently. Well acquainted with how to get runners prepared to compete, Coach Carl came to Agnes Scott with “a vision and a plan for the program and it got people excited to join forces with her” according to Agnes Scott College’s Cross Country Graduate Assistant Coach, River Bonds.

Coach Carl trains Agnes Scott athletes with the same science-based training program that led her to All-American status as a collegiate athlete. Like an astute writer, she uses an outline to guide the training schedule. “I see where our championship races are, then work backwards,” explains Coach Carl. This approach of reverse chronological planning is standard for coaches from all sports to properly peak their athletes for late-season competitions – Agnes Scott’s championship cross country races are usually in November. Next, Coach Carl lays out four, six-week training phases to prepare her athletes for November’s races. In each training phase, specific workouts are featured to enhance certain body processes that improve distance-running performance.

Naturally, the initial training phase is the easiest, as its primary goal is to re-acclimate the athletes to running consistently. Coach Carl may advise athletes who did not run competitively during the spring to build up to running 15 to 30 miles per week over this phase. Not only does this phase prepare athletes for more rigorous training, but it elicits adaptation that improve distance-running performance. For example, to keep running, leg muscles need a constant supply of oxygen-rich blood, like a car engine needs gas. Consistent running increases the stroke volume, the volume of blood pumped from the heart with each beat, which improves the body’s ability to circulate oxygenated blood to leg muscles and keep running.

Once the initial adaptations are in motion, Coach Carl’s athletes transition to the second training phase, where “repetition” workouts are introduced to their weekly schedule. Repetition workouts entail running relatively short and fast intervals with long recoveries between repetitions. For cross country athletes, repetitions workouts are generally 200 to 400 m (a half to full length of an outdoor track) at current mile race pace with 1 to 8-minutes rest. The primary goal of these workouts is to improve athlete’s running form, since optimizing form maximizes performance. Improved running form may decrease the rate of energy that an athlete expends while running a given speed. This is analogous to how much gas a car burns while driving at a constant speed (less gas is better). While considering other factors, athletes who consume less energy to run at a given speed can outperform their competitors by having the ability to run farther at a given speed and faster at given aerobic intensity.

“…Then I get them for the next two phases… when they are back on campus” continues Coach Carl. You read that correctly, 12 of the collegiate 24-week training program is completed prior to the first day of practice. “You have to be intrinsically motivated to do well”, she adds. Indeed.

Athletes are welcomed back to school by the most difficult training phase. By now, each week athletes run multiple easy days, two structured workouts (e.g. repetition workouts), and a long run. Long runs are ~25% of the respective athlete’s weekly mileage (e.g. ~10 mile long run for an athlete running 40 miles a week) and serve to improve the number of blood vessels that transport oxygen to exercising muscles. Notably, the primary goal of the third training phase is to increase the maximum rate of oxygen that an athlete can uptake, transport, and utilize to generate energy. Much like how football players love 40-yard dash times, this is the measure that endurance athletes obsess over due to its close relationship with distance-running performance. To increase her athletes’ maximum rate of oxygen uptake, Coach Carl has the team perform classic “interval” workouts that consist of 3-5 minutes of intense running with 2-3 minutes rest between intervals.

Another intense, albeit a more enjoyable, aspect of phase three are the beginning of cross country races. Cross country races are generally 2.0 to 3.7 miles and start around the end of August or beginning of September. Ideally, Coach Carl’s team runs 5 to 6 races before the November’s championships.

The final training phase is intended to simultaneously improve another physiological process and freshen the athletes up for the key races. Physiologically, to sustain a relatively fast running speed, athletes expend energy without the presence of oxygen at the muscle-level. If athletes expend too much of this energy source, their blood will likely become more acidic than normal, resulting in the sudden feeling of having heavy legs. To train the body to buffer this race-slowing feeling, athlete’s run workouts include a moderately hard continuous run (e.g. 20 minutes) or multiple repeats with short rest (e.g. 5-minute intervals with 1-minute rest). These workouts are perfect for the final training-phase because they are also relatively easy to recover from due to their controlled intensity. In the last few weeks of the season, athletes decrease their overall weekly mileage to enter the championship races rested and ready.

XC Season is finally here!!! Let’s wish our team good luck as they head to their first meet of the season #LeaveALegacy … here’s some footage from the Stone Mountain pre-season run #GoScotties pic.twitter.com/KHQ7xl0s4G

— Agnes Scott Cross Country (@ASCCrossCountry) August 31, 2018

Even though this science-based training approach develops key physiological parameters that influence distance-running performance, Coach Carl carefully customizes the training of her athletes as the season progresses on an athlete-by-athlete basis. “You cannot just plug a human into a system and be like this should totally work out” she says with amusement. Subtleties like altering training to handle life events, mimicking training environments to resemble race courses (e.g. incorporating hills to prepare for hilly courses), and developing race plans that cater to each athlete’s strength are just a few ways that Coach Carl artfully brings science-based training to life.

Whether you are preparing to get back into shape, run in the world’s largest 10-kilometer race (Atlanta Track Club’s Peachtree Road Race), or guide athletes through their cross-country season, these science-based training methods can be helpful. After all, what do you have to lose? Except for a few minutes on your next race.

The Science of Spirits with Old Fourth Distillery

By Kellie Vinal

Old Fourth Distillery, nestled in the heart of Old Fourth Ward, is well known around Atlanta as a purveyor of hand-made vodka, gin, and their signature ginger lemon liqueur, Lawn Dart.

It hasn’t always been easy to get locally sourced spirits, though. In fact, Old Fourth is the first legal Atlanta distillery in over 100 years, due to the temperance movement that forced prolific distillers like R.M. Rose & Company out of the city.

“There’s a really rich history of distilling in Atlanta,” says Jeff Moore, one of the two founding brothers of O4D. If you look closely, you’ll notice that the distillery is teeming with artifacts of the distillers that came before them – some bought, others donated by generous collectors and enthusiasts.

The Moore brothers have a refreshing reverence for history, honoring the folks that pioneered their craft in all they do. Each aspect of the distillery – from the construction of the physical space, the antiques filling each nook and cranny, the design of their bottles and labels, and the spirits they create — has been thoughtfully considered. Each bit is a nod to history, an appreciation of the past.

For instance, many of the materials used to build the space were salvaged and repurposed from the demolition of John B. Gordon Elementary School, a historic, once bustling East Atlanta school built in the early 1900s. The distillery’s marble countertops once served as dividers of the school’s boys’ and girls’ bathroom stalls, and is said to have come from the same batch of marble — mined in Tate, Georgia at the turn of the century — that the Lincoln Memorial is made of.

Jeff acknowledges that although it takes significant work to upcycle old materials in place of buying new ones, it’s worth it.

“We talk about being stewards of the materials that we use,” he says.

The Journey from Yeast to Spirits

The Moore brothers’ thoughtfulness extends to the science behind their craft, too, and necessarily so – creating spirits is actually more complicated than you might think.

At its core, distillation is the process of strategically separating liquids through condensation (which means converting water vapor into liquid water) and evaporation (converting liquid to a gas). But to make gin, vodka, or bourbon, for that matter, it all begins with yeast.

Similar to wine- or beer-making, creating liquor begins with fermentation, or the conversion of sugar to alcohol and carbon dioxide. At O4D, they’ve developed a specific protocol for each type of liquor they make, each requiring a particular strain and precise amount of yeast.

“We could take the exact same recipe that we made our vodka out of and put another yeast strain in and it’ll give us a completely different finish,” says Jeff. “It’s really, really interesting, how the complexities work.”

As such, each batch of yeast must be fed and grown precisely. When making vodka, for instance, Jeff and his team add carefully measured amounts of cane sugar, nutrients, calcium carbonate (to balance the pH), and a few other ingredients to their yeast, and then grow the cultures at specific controlled temperatures.

The yeast undergo multiple cycles of heating and cooling over the next five days, coordinated by human-powered thermostats and control valves galore. As the yeast convert sugar into alcohol, they eventually run out of sugar to consume and ultimately create a 13% alcohol mixture.

“We call it Edgewood hard soda,” Jeff jokes. “It’s [basically] 13% alcohol cane soda, if you will. But we don’t stop there.”

The thing is, yeast don’t like living long-term in 13% alcohol. It’s toxic to them.

That’s where distilling comes in. To get to that higher alcohol content, Jeff and his crew must physically separate the alcohol from the rest of the mixture.

Basically, since the boiling point of alcohol is lower than water, distillers can strategically evaporate the alcohol from their mixture. The next step is to collect the vapors, separate them from the water, and cool them down, thus condensing the vapor back into a liquid. This is all done in a device called a still. At O4D, they use a custom, handmade CARL copper still.

It seems like magic, but it’s science: in a single run, the 13% alcohol mixture becomes 50% alcohol. Jeff and his crew then run the mixture twice more through their still.

For each and every run, the still operators keep detailed logs, tracking which batch of sugar they used, how much of each ingredient they used, any time or temperature tweaks they made throughout the process, and characteristics of the final product.

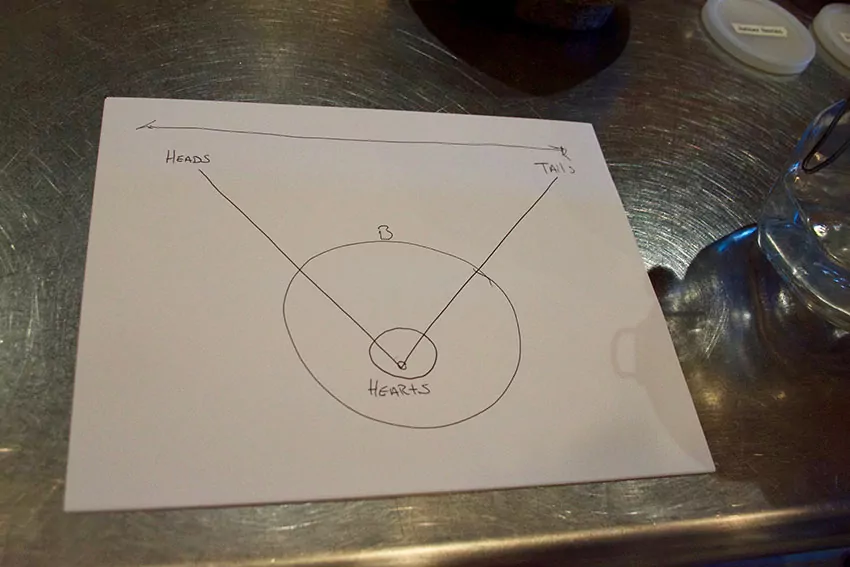

Heads, Hearts, and Tails

The evaporation process of distilling isn’t completely clear-cut – the alcohol you want is inevitably mixed in with some chemicals you don’t want. Jeff explains that with careful temperature and timing control, he can separate out the parts they don’t want and keep the parts they do.

“We’re pulling off three main components [at different temperatures],” Jeff explains. “The heads, the hearts, and the tails. What you want to drink are hearts.”

What comes off first at the lowest temperatures – the heads – are quite toxic, with a distinctly chemical-y smell. The heads get sent off (no joke!) to fuel companies to repurpose for methanol. What comes off last at the highest temperatures – the tails – are lower alcohol content and contain unappetizing oily substances. “It’s very … oily band-aids,” Jeff laughs.

“You’re always going to have some heads and some tails. Always. There’s no getting rid of it all.” Jeff continues, “How you tell is by taste, touch, and smell.”

As with most things, it’s all about finding balance. The optimal middle portion — the hearts — undergoes a few more finishing steps before it’s ready to be bottled, including a sometimes week-long “resting” phase to let everything settle.

Jeff gestures to the hearts as he says, “when we’re distilling, this is the magic. It all boils down to this.”

Experimenters by Trade

When it comes to making spirits, there’s both an art and a science to it. Vodka, gin, and bourbon require very different starting materials, temperatures, time schedules, and manipulations along the way. No two gins are exactly the same, either.

“Gin can have literally anything in it. The only thing that gin has to have in it from a legal standpoint is juniper berries,” Jeff says. “Other than that, the sky is the limit. And believe me, we have tested that theory.”

“The gin that we sell today is my greatest accomplishment in terms of distilling,” Jeff says. He gestures to a shelf filled with bottles. “Up here, we have about a dozen versions of gin.” He continues, “I’ve got a moleskine notebook stashed somewhere and every single one of these has got three pages of notes on how to make it.”

Giving Back

Since Old Fourth Distillery opened its doors in 2014, they’ve made an effort to connect with their community through tours, tastings, and community collaborations. This summer, for instance, they teamed up with Atlanta United to create a limited edition gin that has been enthusiastically received by fans.

Old Fourth finds other ways to give back as well, like maintaining the gravesite of historic distiller R.M. Rose, which is nearby at Oakland Cemetery. They’ve made gin in Rose’s honor, using juniper berries picked near his gravesite. O4D has also forged a friendship with their upstairs neighbor, The Railroad Model Club of Atlanta, periodically helping them with upgrades and generally supporting their endeavors.

With so much intention and precision behind all they do, O4D is poised to serve southern spirits to Atlanta for years to come. To keep up with new releases and updates or to schedule a tour, visit the O4D website. You can also connect with them via Facebook or Twitter.

If you’re curious about the history of distilling in Atlanta, Jeff recommends the book Prohibition in Atlanta by Ron Smith and Mary O. Boyle.

The Science Behind Cheese with Decimal Place Farm

By Kellie Vinal

You might not expect it, but nestled just southeast of the city limits of Atlanta lies a 40-acre oasis of grazing pastures and scrubby brush that 40 adorable adult dairy goats call home. Those in the know will tell you it’s where to find the best goat cheese in town — Decimal Place Farm. A mere 11-minute drive from the Starlight Drive-In Theatre, Decimal Place thrives as a source of freshly made cheeses, delivering feta, mozzarella, creamy chevre, and cheddar to grocery stores, farmers markets, and well-known restaurants around Atlanta.

Mary Rigdon has been running the farm since her family took over the land in 1995, and is a tried-and-true expert of her craft. With a degree in animal science and background in research with pigs, sheep, and cattle, she’s incredibly knowledgeable when it comes to animals. And it shows – she’s raised her herd of Saanen dairy goats since they were little, and they are noticeably trusting and calm in her presence.

“We’re truly all about keeping the animals happy and healthy,” she says. “I love the animals. The better I treat them, and the better I understand them, the better they give back to me.”

Her almost otherworldly intuition puts her goats at ease, and they find comfort in the routine she’s established for them. “Goats are all about routine,” she says. “So, twice a day, at the same time every day – we milk.”

Mary fell in love with Saanen goats – a breed originating from the Saan valley in Switzerland — for their sweet temperaments and superior milking qualities. Over the years, she’s carefully bred and selected her goats for their impressive milk production, as well as their physical characteristics.

“Each animal is identified as to who their mother is and their father is, and I’ve got milk records on the mothers for the last 20 years,” she explains. “I’ve selected all through those years for straight legs, a level top-line, and good feet — so that they can travel through my pastures and do a good job of grazing, which is what they’re meant to do.”

Most days, you can find the goats happily roaming and grazing around the 40 acres of farmland, rotation of which Mary strategically orchestrates to keep both the land and goats healthy.

“They graze the woods that are around us,” she says. “We have poison ivy, privet, honeysuckle, and the goats eat that, along with the tree leaves and the acorns that are around, and they turn it into that tasty milk.”

When baby goats are born, the mother starts giving milk – called lactation – and generally, each goat gives milk for approximately 300 days. The goats at Decimal Place Farm usually give about a gallon a day, if not two, for those 300 days, and Mary and her crew turn it into cheese.

Mary isn’t shy about diving into the science behind it all, either — from the selective breeding to optimization of milk production, to the science behind different kinds of cheeses. Her enthusiasm is palpable as she explains lactation, sketching a curve on the notepad in the milking room.

With a twinkle in her eye, she says, “I eat this [science] stuff up. I love it!”

She explains that, after extensive calculations and cross-referencing of milk records, she’s selected for goats that maintain a long, level lactation curve, rather than a large, brief spike in milk production.

It All Begins With Milk

The process of making cheese starts in the milking room. Mary’s milking room facility accommodates up to ten goats at a time, each of which gets personal attention to ensure they’re in tip-top shape before beginning. Not only are the goats tested in advance for tuberculosis, brucellosis, and other diseases, but their milk undergoes a quick, simple test that confirms each goat is in good health and thus producing healthy milk each day.

Once the goats’ udders are dipped with a bleach solution and wiped clean, and their milk is deemed infection-free, the milking process begins – either by hand or by a vacuum-driven machine that mimics the action of a squeezing hand, gently pumping the milk to a receiver. When the receiver fills up with milk, the milk completes an electrical circuit, activating a pump that transfers the milk up and through the wall to a bulk tank.

The milk stays chilled in the bulk tank until Mary’s ready to make the cheese, which is typically the same day the goats are milked. Each day is different, with local chefs and restaurants requesting a variety of cheeses in different quantities. Mary makes sure she’s ready for anything.

“If one chef for one restaurant wants a cheddar and a chevre, and another restaurant wants a feta, then I can make to the orders that I have that day,” Mary explains, “and that way it keeps the cheese fresh for everyone.”

Each batch of milk is first pasteurized – heated above 146 degrees Fahrenheit for 30 minutes – in order to kill any harmful bacteria, then cooled back down. From there, small batches of milk are processed at a time, undergoing slightly different processes to achieve the desired consistency and taste.

The Transformation From Milk to Cheese

In each case, the basic concept is this: milk exists as an emulsion, meaning that microscopic clumps of milkfat proteins are suspended in a mostly watery environment. At the heart of cheese-making is simply removing the water from milk, concentrating the proteins and fats that are already there into solid curds.

Mary explains that milk contains two types of proteins: casein and whey. Casein proteins have little tails that form a protective surface, preventing the molecules from clumping together. During the process of cheese-making, Mary adds an enzyme called rennet, which slices those little tails off the casein proteins. As a result, the casein proteins begin to lump together – called clotting or coagulation, which sets off a domino-like effect until nearly all of the molecules have clumped together. The milk is converted to a solid – called a curd – and the remaining liquid portion (called whey) is separated.

You can make any kind of cheese with the goat milk, Mary explains: but it’s the temperature, the time, and the amount of good bacteria and rennet you add to the milk that makes the difference. For instance, to make Decimal Place Farm’s signature creamy chevre, Mary adds her culture of good bacteria to a pot of milk with just 5 drops of rennet – a little bit goes a long way with that stuff. Compared to other cheeses, creamy chevre requires more culture, less rennet, a lower temperature, and a much longer incubation time.

She explains that she makes feta cheese using a larger amount of rennet, a much shorter incubation time, and a higher temperature, so the bacteria grow more quickly. Over the years, she’s developed a precise protocol for each type of cheese, giving each type a signature flavor that keeps folks coming back for more.

“Now there’s the art, and there’s the science,” she says with a smile.

“Making cheddar is a long, involved process,” Mary explains, as she twists the handle of a cheddar press, mechanically pressing the cheese to remove excess moisture.

Cheddar cheese undergoes several rounds of moisture removal before it’s sealed in wax, then aged.

Cheese, Love, and Science

When she’s not tending to goats or making tasty cheeses, Mary shares her love of science through her passion for teaching. She regularly leads tours and classes on the farm to curious folks of all ages, guiding groups through pastures and leading cheese-making demonstrations.

Her enthusiasm is infectious as she describes why some cheeses are yellow, while others are white: cows transfer carotenoids (a natural pigment found in grass) from their diet to the milk, where they bind to the fat and end up in the curds. Goats, however, (along with sheep) do not pass carotenoids to their milk, so their milk is white.

Her extensive knowledge comes in handy, especially when she encounters folks with allergies or intolerances to cow’s milk.

“The reason is,” she explains, “goat milk [has] shorter chain fatty acids. A cow milk fat molecule would be the whole alphabet, while a goat milk molecule would be ABCD — a shorter chain.” She continues, “The reason why so many people have tolerated goat milk rather than cow milk, [is that] their stomach acids don’t have to work so hard to break the bonds.”

Whether you’re allergic to cow’s milk or not, the cheese at Decimal Place Farm is absolutely worth a try. If you’d like to check out some of Mary’s cheese for yourself, you can find her at the Freedom Farmers Market at the Carter Center each Saturday. You can also find her cheeses at the East Atlanta Village Farmers Market on Thursdays, and at Rainbow Natural Foods in Decatur. For more information about Decimal Place Farm and where to find their cheeses, you can find them on Facebook, Instagram, or visit Decimal Place Farm’s website.

Tiny ALEX Begins Her Journey to #ATLSciFest 2018 with #TinyDoorsATL

Tiny ALEX (Atlanta’s Lead EXplorer) is ready for #ATLSciFest 2018 and has started to explore the city by visiting one of Atlanta’s most prized public art exhibits – Tiny Doors ATL. Founded in 2014, Karen Anderson and Sarah Meng created this Atlanta-based art project consisting of evolving interactive installation pieces that bring wonder to tiny spaces. Principal Artist and Director Karen Anderson maintains the doors throughout the year and now focuses much of her time on creating tiny art for small businesses and companies. We can thank Karen for our wonderful Tiny ALEX!

ALEX and the Atlanta Science Festival love collaborating with local organizations that offer Atlantans accessible STEAM (Science, Technology, Engineering, Art, and Mathematics) experiences. We’re very thankful to Tiny Doors ATL for doing just that!

If you’re looking for even more Atlanta STEAM experiences, the 2018 Atlanta Science Festival March 9-24 has you covered. The Festival launches on Friday, March 9 with Rise Up, Robots! at the Ferst Center of The Arts and ends with our free Exploration Expo at Piedmont Park on March 24. Plus over 100 events that take place in-between. Plan your festival experience today! And who knows, you just might meet a life-size ALEX along the way.

The Science Behind the Circus with Imperial OPA

How do circus performers balance a ladder on their chin? How does inertia affect aerial shows? The science behind the circus is both intriguing and entertaining, so we’ve turned to Imperial Opa member John Indergaard to help us learn a bit more.

Imperial Opa member John Indergaard shows off his juggling skills in their practice facility!

John, a self-described “general goofy person,” began juggling at seven-years-old in P.E. class and turned the skill into one of his favorite hobbies after his mom bought him juggling clubs for his birthday.

John’s introduction to the circus actually happened thanks to the Atlanta Science Festival. John was studying physics with a research focus on molecular beams at Georgia Tech. While hanging out in the demo room of the Howey Physics building one day, John and a friend gave a tour to a professor who wanted to create a “science of the circus” event for the upcoming Atlanta Science Festival. Naturally, John’s ears perked at the chance to incorporate his favorite hobby and his passion for math and science. Since then, John joined the circus and has become the science expert at Imperial Opa, leading our annual Science of the Circus event each year at the Festival. We hung out one night at circus practice with John to learn more about how he intertwines his two passions at one of Atlanta’s best circus acts in town.

What areas of science are involved in circus performance?

Every circus act can be viewed through the eyes of a scientist. Scientific thought can be used to analyze anything in nature, so I would say that I dissect circus feats through scientific scrutiny more than develop acts based off of scientific principles.

Partner acrobats take hours of practice and teamwork! The scientific trick to these poses comes in analyzing the center of mass, since there can be several acrobats at a time leaning away from each other.

Tell us more about how you use science to perfect your craft.

The great thing about using the circus as an avenue of science outreach is the ubiquity of circus arts in the world and the large degree of separation between circus and science. When people think of circus they probably don’t think of science at all, and vice versa. When an audience, particularly younger students, are presented with an amazing circus act that is given a detailed scientific description it brings up a conflict in their minds: How is this person making the circus about science? What does science have to do with anything here? I try to use these moments to help people realize that science was not created for the classroom or made to be a boring homework assignment, but rather science has been cultivated for thousands of years to give us the most useful and detailed methods to learn something from the world around us – whether that be atomic physics, chemical reactions, or an acrobat on the trapeze! Science can be everywhere around us!

This act uses balancing, juggling, and partner acrobats to wow their audience!

What are the main acts of your circus? Could you walk us through the science of each of them?

Sure thing! I’ve broken down the science behind aerial, partner acrobats, tumbling, balancing/juggling, and our fire show below.

Aerial

Aerial

Aerial acts can be performed on silks, lyra, rope, trapeze, and other apparatus. When we scientifically analyze these acts we focus on the rotational motion of the aerialist. Specifically, we like to discuss spinning and how the positioning of our arms affects our rotation. Arm position changes your body’s tendency to resist acceleration as it rotates around an axis – extended arms slow the rotation, while tucked arms speed you up. This helps maintain a law of nature – conservation of angular momentum – which depends on rotation speed and shape of the rotating object. If shape changes, then the speed must compensate to conserve angular momentum by changing as well. Aerialists use this principle of physics to seamlessly transition from rapid rotations to slow elegant motions.

Partner Acrobats

Partner Acrobats

Partner acrobatics often demonstrate amazing feats of strength and flexibility, stacking and tangling many people together. We like to demonstrate positions that look odd due to acrobats leaning or hanging from one another. The scientific trick to these poses comes in analyzing the center of mass, since there can be several acrobats leaning away from each other whom look like they should be falling over. However, the center of mass always remains above the stable point (like feet on the ground) even though there is no physical mass at that position! In these cases, a basic understanding of physics can change the way that acts are viewed.

Tumbling

Tumbling

Watching our tumblers jump and flip over each other and audience members always puts a smile on people’s faces! The physical concept demonstrated here is the conversion of linear momentum into angular momentum, like when an acrobat is running in a straight line and all of a sudden tucks into a rapidly rotating position as they make a flip. Since momentum is always conserved, acrobats take their linear momentum (running in an extended body position) and rapidly convert it into angular momentum (flipping with arms and legs tucked). That is why you see these acrobats running so quickly before performing their feats – with all that momentum built up all they have to do is change their body position ever-so-carefully to generate the rotation necessary to perform their amazing flips and twists.

Balancing/Juggling

Balancing and Juggling

The language of juggling is truly the language of mathematics. All juggling tricks can be described using numbers that represent the number of beats the objects spend in the air, and where the object begins and ends its pattern. Ignoring gritty details, generally speaking odd numbers describe throws that are thrown and caught by different hands while even numbers describe throws to the same hand, with larger numbers of objects requiring higher throws (see siteswap.org for more on this). Perhaps not surprisingly, if you ask a juggler, it is very common for them to have some background or interest in science and mathematics.

Balancing is fascinating from a physical point of view. This boils down to the center of mass and moment of inertia (that is, the tendency to resist rotation) of various objects that a circus performer may want to balance on their chin, or nose, or forehead. An object with its center of mass higher up will have a larger moment of inertia and therefore will require more time to fall. These objects fall more slowly and thus are easier to balance. For instance, it is always amazing to see a performer balance something large like a ladder on their chin, but since the center of mass of the ladder is so high it is actually relatively simple to balance compared to something less impressive like a fork or spoon!

Fire Shows

Fire Show

A scientific view of fires requires chemistry! Choosing a fuel with a low burning temperature to allow the performer the most comfort and a high burning efficiency to reduce smoke is essential for a successful fire performance. There can even be fuel chemical additives to allow fantastic colors in the flames! A performer must also understand the idea of ignition temperature, since a wick doesn’t need to be flaming to reignite when reintroduced to the fuel.

What is your favorite part of the circus? Can you share any science secrets about conducting it?

My favorite part of being in the circus is getting such undivided attention from kids who are amazed at all of the diverse acts! Using this amazement to bring young people into a scientific discussion is a slick little trick I like to use to insert science into their everyday lives, especially when they least expect it.

Stay tuned for more information on Imperial Opa’s upcoming #ATLSciFest event in March 2018!

The Science Behind Ice Cream with High Road Ice Cream

How is the matter that makes up traditional ice cream, soft serve, custard, and sherbet different? What elements make ice cream the chilly, luxurious treat we all love? The science behind ice cream is both fascinating and delicious, so we’ve turned to High Road Ice Cream owner Keith Schroeder to help us learn a bit more.

Keith Schroeder, High Road’s Founder and CEO, is the first to admit science comes first when making luxury ice cream!

As CEO of High Road Ice Cream, Keith Schroeder will be the first to admit ice cream is science first and everything else comes second. As a chef, Keith didn’t have to worry too much about temperature, engineering, or numbers. But after taking his love of ice cream to the next level, he quickly found adding in machinery on a large scale can become very overwhelming. “I had to become a student of the technical nuance or else… I’d become toast,” Schroeder joked.

Atlanta Science Festival Co-Director Meisa Salaita talks with Keith Schroeder about the science behind ice cream production.

Schroeder does not actually have a formal science background, but as he discussed the craft of ice cream making, it became clear that he quickly had to become an expert in the study of food science, namely topics like emulsification, freezing point depression, solutions, microbiology, and the science of flavor. Continue reading to learn more about his scientific journey!

Friends and neighbors can get a glimpse behind the window to see, taste, and purchase products every Saturday from 10AM-2PM!

Walk us through the process of making ice cream from a scientific perspective.

Ice Cream, in a scientific sense, is a foam, solid, and liquid all at once. There are some solids from fats and some from proteins which we have to treat differently, as they respond to agitation differently. To create our base mix, from a scientific perspective, we usually need to think about fats, non-fat solids, water, sugars, and emulsifiers for stabilizing. In a classic sense, that translates to dairy milk, cream, milk solids, sugars, and egg yolks. Then when you want to add flavoring, it throws the base mix out of balance, so you always need to adjust your base mix for whatever you are adding.

Simply stated, the differences in the components of different styles of ice cream are:

- Soft Serve is lower in fat and higher in solids

- Custard-based ice creams are richer with the addition of egg yolks

- Philly style ice cream tends to be high butterfat, no yolks.

- Gelato is a largely generic and unregulated term that allows US manufacturers to not meet the butterfat requirements for ice cream and is ultimately a cheaper product in the US. Where it is high quality, it’s a stylistic shift that raises sugars and lowers fats – yielding a brighter tasting end product.

What part of ice cream making is the most difficult? Can science help with that?

Automating production is the most challenging, as you’re trying to push very stiff ice cream through stainless pipes while folding caramels and chocolates and other inclusions into the automated stream of ice cream. When you grow your business and start to use machinery that has a very specific functional purpose, you can no longer use your hands in the same way and need to be much more familiar with what is going into the machines – thinking of composition, thermodynamics, phase states, fat agglomeration issues, and so forth. Engineers are priceless in the ice cream industry. For example, the length of a pipe can be very important in the texture of the final outcome. When you are a chef, you don’t think that way. No one ever tells you that if a knife were half an inch longer, the food would taste better!

High Road’s Chief Manufacturing Officer Steven Roddy shows us the pasteurizing room where their unique process kills bacteria while maintaining a delicious fat content in their base mixture. One of the biggest investments in the company is taking care of food safety. The High Road team is constantly checking to be sure the facility is clear of harmful pathogens like Listeria and coliform bacteria (like E. coli).

These 300 lbs and 500 lbs tanks heat the mixture to 160F for 30 minutes. Afterwards, the mixture is then homogenized by equipment from the 1960’s! The pistons in the homogenizer blend the mixture together to achieve the perfect incorporation of fat, water, cream, and sugar.

Which method of ice cream making do you use and why?

We employ all techniques, as we have customers with different needs. We pride ourselves on meeting challenges presented by customers. For example, for our High Road branded products, we vat pasteurize our milk and cream. This method heats the milk/cream mixture low and slow which denatures the proteins differently than the faster pasteurization process normally employed by ice cream makers and results in what we feel is a better texture final ice cream.

Other than how you pasteurize the milk and cream, what determines texture and consistency?

Mix formulation, proper ice cream making equipment, and temperature – rapid deep freezing, and proper storage during transportation (-20F).

Classic and exotic flavors await consumption in -20F!

Tell us more about the role temperature plays in making ice cream. How does temperature affect taste and texture once you’ve made it?

The rate of freezing is very important to making ice cream, thinking of how aggressive the method you are using is in removing heat from the product. If you freeze too quickly, you don’t have the opportunity to churn and get the texture you are looking for. Freon in the machines like we have here is the best. A mixture of ice and salt would be the second best choice. By mixing the right ratio of salt and ice together, you can make a solution that is cold enough to freeze the ice cream at the proper rate.

After the ice cream is made, the temperature continues to play a huge role. The ice crystals that are created during formulation are finite – not detectable to the tongue. But if the temperature is shocked (going above 10F during transport), the tiny seed crystals in the ice cream grow and ruin the intended texture of the ice cream. This is also what you see if you leave ice cream in your freezer for too long.

After the sweet cream mixture has aged, it’s time to add the fresh ingredients!

How does the fat in milk affect the process of making ice cream? Can you make ice cream out of milk from any animal?

Fat must be somewhere between 12 and 18 percent to yield a good quality ice cream. Ice cream can be made from milk and cream from any animal, yes. However, cow’s milk is brightest, sweetest, and most abundant. It’s also quite neutral in flavor.

How does air influence in the process of making ice cream and keeping it fresh?

Air is incorporated as a function of churning, and too much air degrades the mouth-feel and quality perception of ice cream. Also, keeping ice cream containers air-tight prevents surface crystallization and keeps the ice cream from taking on off-flavors from the freezer environment.

What is the importance of using regionally-sourced ingredients?

It’s important if the regional item is superior in quality and/or meets our food safety standards. Pecans, peanuts, peaches, and blueberries are exceptional in Georgia.

High Road creates their flavors from scratch by using fresh ingredients which helps their ability to avoid Listeria outbreaks and ensure their products are safe for consumption.

How and at what stage do you incorporate the different flavors? Have you ever had a flavor not taste at all how you were expecting?

Flavoring happens after the mix is refrigerated overnight, and after it’s metered for production. A chef and a quality manager work together to monitor the flavoring of every batch. We must monitor the inputs closely to ensure that the ingredients beyond the ice cream mix ingredients meet our strict quality standards. It’s a craft, requiring attentiveness from the chefs, so yes, there have been times where flavors have missed the mark. We typically catch those off flavors before producing the ice cream, though.

Chefs and quality managers monitor the input of ingredients closely to ensure that the ingredients beyond the ice cream mix meet their strict quality standards.

Once the ice cream is made, how can packaging make or break the end product?

Packaging must be airtight, allow for airflow in the deep freezers, and stand-up to scooping – either by the consumer or professional. We tend to use industry tested and proven packaging. We’d rather innovate in ice cream than risk a failure with new packaging.

High Road’s Marietta plant uses ingredients from Mexico, Japan, Thailand, Canada, Tanzania, Ivory Coast, and Madagascar!

What is your favorite flavor of ice cream and can you share any science secrets about making it?

Vanilla. Because vanilla extract is made with alcohol, it’s important to use a double-fold (high concentration) vanilla in ice cream, otherwise, the ice cream can taste boozy, which isn’t welcome in a straight-ahead vanilla ice cream.

Owner Keith Schroeder’s favorite flavor of ice cream is vanilla!

Thank you to High Road Ice Cream and Meisa Salaita for walking us through the science behind ice cream. Stay tuned to our website, Facebook, Twitter, and Instagram for more Awesome Science of Everyday Life features and other festival updates!