The Science Behind Ice Cream with High Road Ice Cream

How is the matter that makes up traditional ice cream, soft serve, custard, and sherbet different? What elements make ice cream the chilly, luxurious treat we all love? The science behind ice cream is both fascinating and delicious, so we’ve turned to High Road Ice Cream owner Keith Schroeder to help us learn a bit more.

Keith Schroeder, High Road’s Founder and CEO, is the first to admit science comes first when making luxury ice cream!

As CEO of High Road Ice Cream, Keith Schroeder will be the first to admit ice cream is science first and everything else comes second. As a chef, Keith didn’t have to worry too much about temperature, engineering, or numbers. But after taking his love of ice cream to the next level, he quickly found adding in machinery on a large scale can become very overwhelming. “I had to become a student of the technical nuance or else… I’d become toast,” Schroeder joked.

Atlanta Science Festival Co-Director Meisa Salaita talks with Keith Schroeder about the science behind ice cream production.

Schroeder does not actually have a formal science background, but as he discussed the craft of ice cream making, it became clear that he quickly had to become an expert in the study of food science, namely topics like emulsification, freezing point depression, solutions, microbiology, and the science of flavor. Continue reading to learn more about his scientific journey!

Friends and neighbors can get a glimpse behind the window to see, taste, and purchase products every Saturday from 10AM-2PM!

Walk us through the process of making ice cream from a scientific perspective.

Ice Cream, in a scientific sense, is a foam, solid, and liquid all at once. There are some solids from fats and some from proteins which we have to treat differently, as they respond to agitation differently. To create our base mix, from a scientific perspective, we usually need to think about fats, non-fat solids, water, sugars, and emulsifiers for stabilizing. In a classic sense, that translates to dairy milk, cream, milk solids, sugars, and egg yolks. Then when you want to add flavoring, it throws the base mix out of balance, so you always need to adjust your base mix for whatever you are adding.

Simply stated, the differences in the components of different styles of ice cream are:

- Soft Serve is lower in fat and higher in solids

- Custard-based ice creams are richer with the addition of egg yolks

- Philly style ice cream tends to be high butterfat, no yolks.

- Gelato is a largely generic and unregulated term that allows US manufacturers to not meet the butterfat requirements for ice cream and is ultimately a cheaper product in the US. Where it is high quality, it’s a stylistic shift that raises sugars and lowers fats – yielding a brighter tasting end product.

What part of ice cream making is the most difficult? Can science help with that?

Automating production is the most challenging, as you’re trying to push very stiff ice cream through stainless pipes while folding caramels and chocolates and other inclusions into the automated stream of ice cream. When you grow your business and start to use machinery that has a very specific functional purpose, you can no longer use your hands in the same way and need to be much more familiar with what is going into the machines – thinking of composition, thermodynamics, phase states, fat agglomeration issues, and so forth. Engineers are priceless in the ice cream industry. For example, the length of a pipe can be very important in the texture of the final outcome. When you are a chef, you don’t think that way. No one ever tells you that if a knife were half an inch longer, the food would taste better!

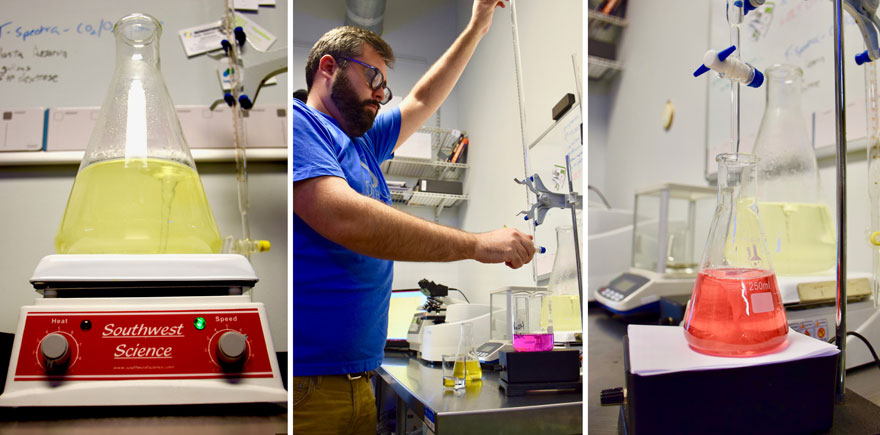

High Road’s Chief Manufacturing Officer Steven Roddy shows us the pasteurizing room where their unique process kills bacteria while maintaining a delicious fat content in their base mixture. One of the biggest investments in the company is taking care of food safety. The High Road team is constantly checking to be sure the facility is clear of harmful pathogens like Listeria and coliform bacteria (like E. coli).

These 300 lbs and 500 lbs tanks heat the mixture to 160F for 30 minutes. Afterwards, the mixture is then homogenized by equipment from the 1960’s! The pistons in the homogenizer blend the mixture together to achieve the perfect incorporation of fat, water, cream, and sugar.

Which method of ice cream making do you use and why?

We employ all techniques, as we have customers with different needs. We pride ourselves on meeting challenges presented by customers. For example, for our High Road branded products, we vat pasteurize our milk and cream. This method heats the milk/cream mixture low and slow which denatures the proteins differently than the faster pasteurization process normally employed by ice cream makers and results in what we feel is a better texture final ice cream.

Other than how you pasteurize the milk and cream, what determines texture and consistency?

Mix formulation, proper ice cream making equipment, and temperature – rapid deep freezing, and proper storage during transportation (-20F).

Classic and exotic flavors await consumption in -20F!

Tell us more about the role temperature plays in making ice cream. How does temperature affect taste and texture once you’ve made it?

The rate of freezing is very important to making ice cream, thinking of how aggressive the method you are using is in removing heat from the product. If you freeze too quickly, you don’t have the opportunity to churn and get the texture you are looking for. Freon in the machines like we have here is the best. A mixture of ice and salt would be the second best choice. By mixing the right ratio of salt and ice together, you can make a solution that is cold enough to freeze the ice cream at the proper rate.

After the ice cream is made, the temperature continues to play a huge role. The ice crystals that are created during formulation are finite – not detectable to the tongue. But if the temperature is shocked (going above 10F during transport), the tiny seed crystals in the ice cream grow and ruin the intended texture of the ice cream. This is also what you see if you leave ice cream in your freezer for too long.

After the sweet cream mixture has aged, it’s time to add the fresh ingredients!

How does the fat in milk affect the process of making ice cream? Can you make ice cream out of milk from any animal?

Fat must be somewhere between 12 and 18 percent to yield a good quality ice cream. Ice cream can be made from milk and cream from any animal, yes. However, cow’s milk is brightest, sweetest, and most abundant. It’s also quite neutral in flavor.

How does air influence in the process of making ice cream and keeping it fresh?

Air is incorporated as a function of churning, and too much air degrades the mouth-feel and quality perception of ice cream. Also, keeping ice cream containers air-tight prevents surface crystallization and keeps the ice cream from taking on off-flavors from the freezer environment.

What is the importance of using regionally-sourced ingredients?

It’s important if the regional item is superior in quality and/or meets our food safety standards. Pecans, peanuts, peaches, and blueberries are exceptional in Georgia.

High Road creates their flavors from scratch by using fresh ingredients which helps their ability to avoid Listeria outbreaks and ensure their products are safe for consumption.

How and at what stage do you incorporate the different flavors? Have you ever had a flavor not taste at all how you were expecting?

Flavoring happens after the mix is refrigerated overnight, and after it’s metered for production. A chef and a quality manager work together to monitor the flavoring of every batch. We must monitor the inputs closely to ensure that the ingredients beyond the ice cream mix ingredients meet our strict quality standards. It’s a craft, requiring attentiveness from the chefs, so yes, there have been times where flavors have missed the mark. We typically catch those off flavors before producing the ice cream, though.

Chefs and quality managers monitor the input of ingredients closely to ensure that the ingredients beyond the ice cream mix meet their strict quality standards.

Once the ice cream is made, how can packaging make or break the end product?

Packaging must be airtight, allow for airflow in the deep freezers, and stand-up to scooping – either by the consumer or professional. We tend to use industry tested and proven packaging. We’d rather innovate in ice cream than risk a failure with new packaging.

High Road’s Marietta plant uses ingredients from Mexico, Japan, Thailand, Canada, Tanzania, Ivory Coast, and Madagascar!

What is your favorite flavor of ice cream and can you share any science secrets about making it?

Vanilla. Because vanilla extract is made with alcohol, it’s important to use a double-fold (high concentration) vanilla in ice cream, otherwise, the ice cream can taste boozy, which isn’t welcome in a straight-ahead vanilla ice cream.

Owner Keith Schroeder’s favorite flavor of ice cream is vanilla!

Thank you to High Road Ice Cream and Meisa Salaita for walking us through the science behind ice cream. Stay tuned to our website, Facebook, Twitter, and Instagram for more Awesome Science of Everyday Life features and other festival updates!